qmtvision

The qmt standard for machine vision applications

qmtvision for machine vision systems

qmtvision enables the realization of machine vision applications in the areas of quality control and process automation. qmtvision includes functionalities specific to machine vision for QMTMesure software. qmtvision is offered in qmt products but it is also used as part of the qmtm4u program for creating custom systems.

qmtvision is a component of QMTMesure which can be completed by qmtsubface for appearance control and qmtsoud for acoustic and vibration control. qmtsixsigma functions and services are available as an option for the intelligent control of machining machines in order to increase production yields and part quality.

qmtvision offers specific functions by profession integrated into qmtmesure software (basic or optional). This function allows a high level of performance while remaining very easy to use. qmtlayercontrol is an example of this type of function.

- Complete and compatible hardware platform, provided by market leaders to guarantee maintenance and sustainability

- qmtmeasure software: without programming, with assisted or expert programming

- Versatile for dimensional measurement applications, appearance checks, text and code reading, assembly checks and print checks

- QMTCom standard communication and synchronization via I/O, TCP-IP and fieldbus

Guarantee the accuracy of measurement

qmt has developed and implemented the QMTJust algorithm and thus improve the measurement accuracy by 16x to achieve << 1µm errors

More information

QMTCalqueControl is a function of QMT Vision Inspector

The QMTCalqueControl function allows DXF superposition and automatic control by measuring the difference between the theoretical value of the plane and the real value of the part over the entire contour.

- Superposition with automatic positioning of the DXF on the image with management of the subpixel to increase precision

- The management of several DXF in several colors

- Compatibility and speed of execution with large DXFs (> 10MB) and very high resolution images (50MPix)

- The measurement of the deviation between the nominal value and the part is measured at all points of the contour

- A simple visualization of the differences by a gradient from yellow to red

- Filtering measures

- The automatic OK / KO decision based on the tolerances set

The metrological functions available

| Functions | Description | QMTM Measurement-Base | QMTMesure-Pro | QMTMesure-Expert |

|---|---|---|---|---|

Measures the total length of a part | ||||

Measure a length between edges | ||||

| Measures multiple lengths of the same part | ||||

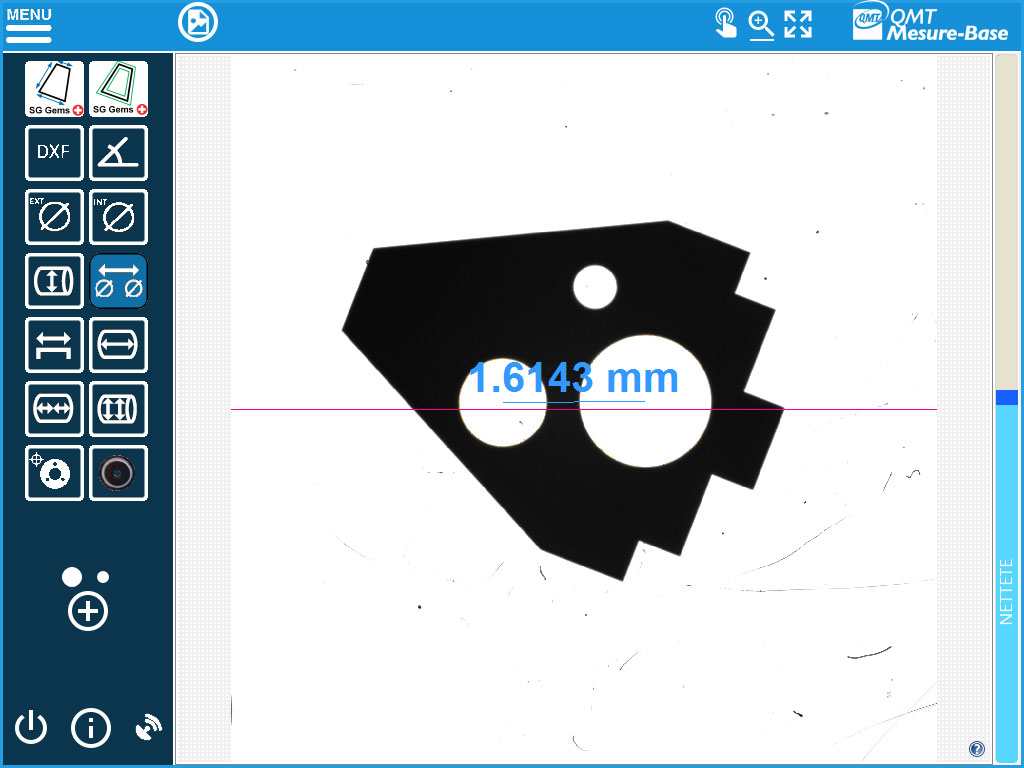

Measure the center distance between two holes | ||||

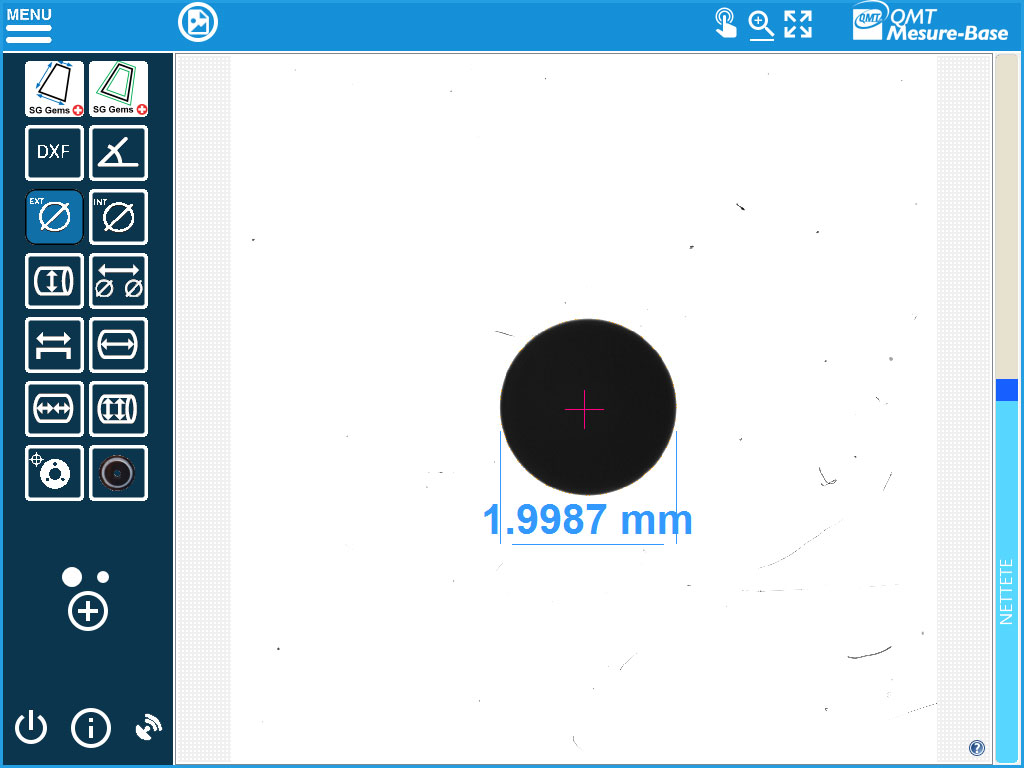

Measures the inside diameter of a hole | ||||

Measures the outside diameter of a part | ||||

| Measures the diameter of a part in profile view | ||||

| Measures multiple outside diameters of the same part in profile view | ||||

| Measure the angle between two edges | ||||

| Measure a gauge plane: a diameter at a defined distance from a reference face | ||||

Measures all the dimensional parameters of a toothed wheel | ||||

Measures all the dimensional parameters of watch stones. Several stones can be measured simultaneously | - | |||

| Measures the position of watch anchor lifts | - | |||

| TAP | Tap measurement according to standard | - | ||

| SCREW | Measurement of all screw characteristics | - | ||

| 3 HOLES | 3 hole GPS location measurement | - | ||

| QMTCalqueControl Overlay | DXF overlay version of QMTCalqueControl | |||

| QMTCalqueControl Measured | Automatic part contour control against DXF | - |

All solutions are based on unique software functions

For optical control

To increase production yields

and the quality of the parts

For aesthetic control

For acoustic and vibration control